Alma-BED was born as a production company of Polyurethane Foam and has evolved by gradually integrating all the phases of the production chain of MATTRESSES, TOPPERS and PILLOWS.

Thanks to our expertise in all stages of the supply chain, Alma is able to support companies operating in the world of BEDDING with partnerships, collaborations or ad hoc supplies.

- Research and development

- Production

- Laboratory analysis

- Foam processing: cutting and gluing

- Assembly, pressing and rolling

Research and development

There is no production without continuous research, our research laboratory is always oriented towards finding innovative foams in terms of effectiveness, sustainability, durability and vacuum resistance.

An interdisciplinary product team studies new solutions to innovate the BEDDING market in terms of foams, cutting methods, comfort and packaging methods/materials. The projects are first created and studied in our laboratory and then, if they meet expectations, produced on a large scale.

This activity guarantees our customers the possibility of selecting the most suitable products for the realization of the mattresses, toppers and pillows they have in mind.

Production

This is where the magic happens: TDI, MDI, additives and other chemical elements are mixed together and become rubber, memory foam and visco thanks to the teamwork of our production departments.

Competence, organization and harmony of our teams, attention to the research of raw materials and innovation are the key to creating quality products.

Each foam has its own characteristics, its own capacity, its own hand, its own price: many types to choose from to make your MATTRESS, TOPPER or PILLOW.

Laboratory analysis

At the end of production, each batch of foam is subjected to a set of codified and detailed analyzes to verify that it complies with the defined quality standards.

In our laboratory, our technicians have state-of-the-art equipment at their disposal with which, on each foam produced, they check: density, lift, resistance to compression and vacuum, hardness, elasticity and much more, depending on the need.

All results are recorded by production batch, historicised, analyzed and interpreted. They are available for the company, and for the customer also.

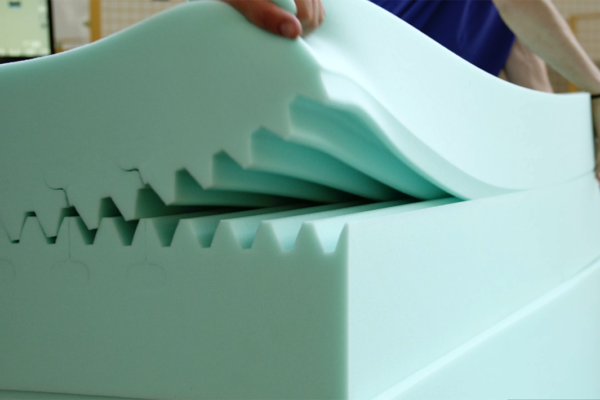

Foam processing: cutting and gluing

It is in this phase that your product takes shape, passing from a block or visco to a MATTRESS/TOPPER or PILLOW.

The polyurethane block can be worked in many ways using, even in combination, different cutting machines:

the cutter to put the blocks to size

the carousel for making linear sheets

the shaping machine for processing with particular shapes

All cutting machines are connected to our computer system and technical design system. In the case of products such as multi-layered MATTRESSES and TOPPERS, the sheets, whether smooth or shaped, in rubber or memory foam, are glued using an ad-hoc industrial plant.

Assembly, pressing and rolling

In this phase, the mattresses and toppers are covered with the selected covers, then enter one of our packaging plants where they are first pressed and vacuum-packed and then, depending on the needs, also folded and rolled. Finally, if necessary, they are boxed in standard boxes or nano packages and then stored.

That’s it: your MATTRESS, TOPPER or PILLOW is ready!